Pharmaceutical process chemistry has come a long way since wholesale merchants began the commercial marketing of drugs in the 19th century. In fact, process chemistry has driven many of the key milestones in drug development over the last 100+ years.

Pharmaceutical process chemistry has come a long way since wholesale merchants began the commercial marketing of drugs in the 19th century. In fact, process chemistry has driven many of the key milestones in drug development over the last 100+ years.

Hydrogenation is an excellent example of a proven chemistry technique that is vital to modern drug discovery and development.

Why?

Chiral chemistry. Hydrogenation drives the field of chiral API synthesis.

Hydrogenation for API Synthesis

Hydrogenation refers to a chemical process in which molecular hydrogen (H2) is reacted with another compound, typically in the presence of a catalyst such as palladium or nickel. Catalytic asymmetric hydrogenation gives rise to a diverse array of chiral molecules useful for producing APIs.

The process involves the reduction of unsaturated compounds, often alkenes, to introduce one or two chiral centers. In turn, chirality plays a critical role in shaping a drug’s pharmacology by refining its target selectivity.

More than half of drugs on the market contain one or more chiral centers to ensure better binding affinity and stereoselectivity. However, achieving ideal compound chirality can be challenging.

Hydrogenation is a practical and convenient technique that is well-established in pharmaceutical process development. Its popularity and broad use are attributable to several key factors, including:

- Versatility

Hydrogenation is capable of an impressive range of chemical transformations, one of the principal reasons for its use. As mentioned above, its role in generating chiral molecules has been vital to API synthesis. Hydrogenation processes can involve heterogeneous or homogeneous catalysis depending on the level of selectivity needed. Catalytic hydrogenation can be fine-tuned for efficiency by modifying a variety of factors, including reaction conditions, catalyst selection, and the use of flexible equipment and methodologies. - Efficiency

The catalytic hydrogenation of pro-chiral compounds shows constant high conversions and remarkable enantioselectivity. It is an economical, high-yield process that avoids the need for super high temperatures and does not generate large amounts of waste. These traits are why interest in hydrogenation processes – with an eye toward scalability – has become so prevalent among pharma companies. - Sustainability

Green criteria for catalytic hydrogenation include using a clean and abundant resource (H2), recovery and recycling of catalysts or unreacted H2, sufficiently low catalyst loading, minimalized use of organic solvents, and closed reaction systems to prevent harmful emissions to the environment. These are practical conditions that can easily be achieved via optimally designed hydrogenation processes utilizing suitable reaction parameters. - Simplicity

Hydrogenation isn’t rocket science (though it does require expertise). For example, hydrogenation processes often use simple batch multipurpose reactor technology. The unsaturated substrate, hydrogen, and the catalyst are completely blended inside a high-performance hydrogenation reactor with a well-designed agitation system. Filtration of reaction mass then separates the solid catalyst from the suspension of the hydrogenated substance.

3-Step Guide to Scaling Up Hydrogenation Processes

There’s no denying the appeal of hydrogenation from both an economical and environmental perspective, but – and ultimately this is one of the most important questions in drug commercialization – is it scalable? There are a number of scales between bench and multi-ton bulk manufacturing. Translating processes across those scales is rarely linear – or straightforward.

Hydrogenation is quite scalable, but success hinges on 3 things:

- A 3-Step Mass Transfer

Hydrogen treatment typically occurs within a three-phase reactor. It involves first mass transfer from gas phase to liquid phase, then liquid to solid phase, and finally transfer into the porous catalyst. Therefore, an optimized mass transport system is necessary to prevent variation in reactor performance.

- Hydrogen Delivery

A widely popular hydrogen feed system is the EKATO hydrogenation reactor, which uses hollow-shaft gassing agitator technology. The hydrogen is fed from the bottom of the hydrogenation reactor for dispersal into very fine gas bubbles. The best hydrogen feed system should allow for varying hydrogen delivery rates based on the required pressure build-up and specific point of process. Recycling unreacted H2 is also vital for economic reasons. - Thermal Control

Hydrogenation demands heat. However, the reaction becomes exothermic once the process gains momentum, resulting in temperature runaway. It’s important to maintain a tight rein on thermal and flow parameters which can impact reaction performance. Since massive amounts of heat must be dissipated (exothermic flux removal), performing thorough heat transfer calculations can minimize issues with heat exchange.

Command of these 3 essential concepts will streamline the step up to large-scale production from laboratory/pilot plant hydrogenation. In addition, it will prevent surprises once hydrogenation in the plant commences.

Contact us today and learn how Neuland can help advance your chiral chemistry project.

Curious about Hydrogenation at Neuland?

Neuland’s investment in state-of-the-art hydrogenation capabilities has delivered key successes to our clients – from enhanced product development capabilities and improved operational efficiency to expedited time-to-market and more flexible manufacturing arrangements.

Our hydrogenation capabilities span every step of the process and include the following:

- Development of hydrogenation processes.

Our expert hydrogenation team establishes optimized laboratory reactor conditions to facilitate meaningful process characterization before full-scale production. They apply their knowledge and appropriate tools, such as Differential Scanning Calorimetry (DSC) and Reaction calorimeter RC1, to conduct a thorough safety evaluation.

- Process scale-up.

We’ve developed a comprehensive toolbox of proven methodologies that incorporate various stereoselective transformations. Our process development and engineering work ensures successful, large-scale batch processes.

- Customer specifications.

The beauty of hydrogenation lies in its versatility and accommodation of a changing product spectrum. We use flexible technology and equipment to develop customer-specific hydrogenation processes that meet various specific needs.

- High-performance equipment.

State-of-the-art, industrial-scale equipment includes a high-performance hydrogenation reactor and batch hollow-shaft gassing agitator. These tools enable us to fine-tune highly specific operating ranges and efficiencies, whether in the lab or at the plant level.

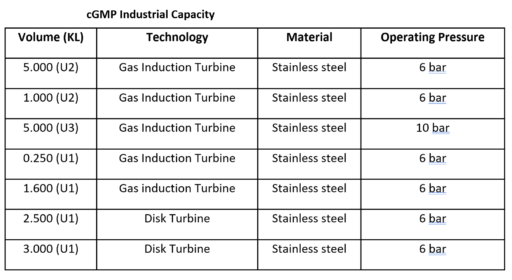

- cGMP compliant capacity.

Our industrial-scale, cGMP compliant hydrogenation capacities are as follows:

cGMP Industrial Capacity

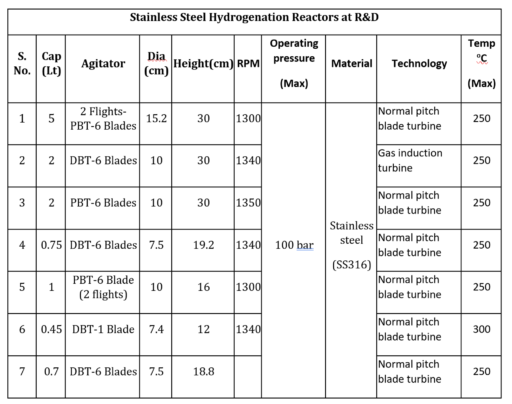

Neuland also offers substantial hydrogenation capabilities for R&D projects, allowing us to scale your process as needed from the bench through commercial production:

R&D Capacity