Why the CDMO Industry Matters More Than Ever in Drug Development

In drug development, even a six-month delay can cost millions, or worse, cost lives. Building in-house manufacturing from scratch is risky as well as inefficient.

That’s why more pharmaceutical and biotechnology firms are partnering with contract development and manufacturing organizations (CDMOs) to ensure speed, quality, and regulatory strength from the start.

What is a CDMO? (CDMO Meaning and Scope)

A CDMO specializes in providing comprehensive services from drug development through drug manufacturing on a contractual basis.

A reputable organization typically has expertise in areas such as medicinal or process chemistry, analytical method development, scale-up engineering, and full Good Manufacturing Practice (GMP) production compliance.

Some CDMOs also provide packaging, supply chain management, and regulatory support as ancillary services, coordinating everything needed to launch and supply a product globally.

Throughout these stages, CDMOs work under strict regulatory standards to ensure compliance.

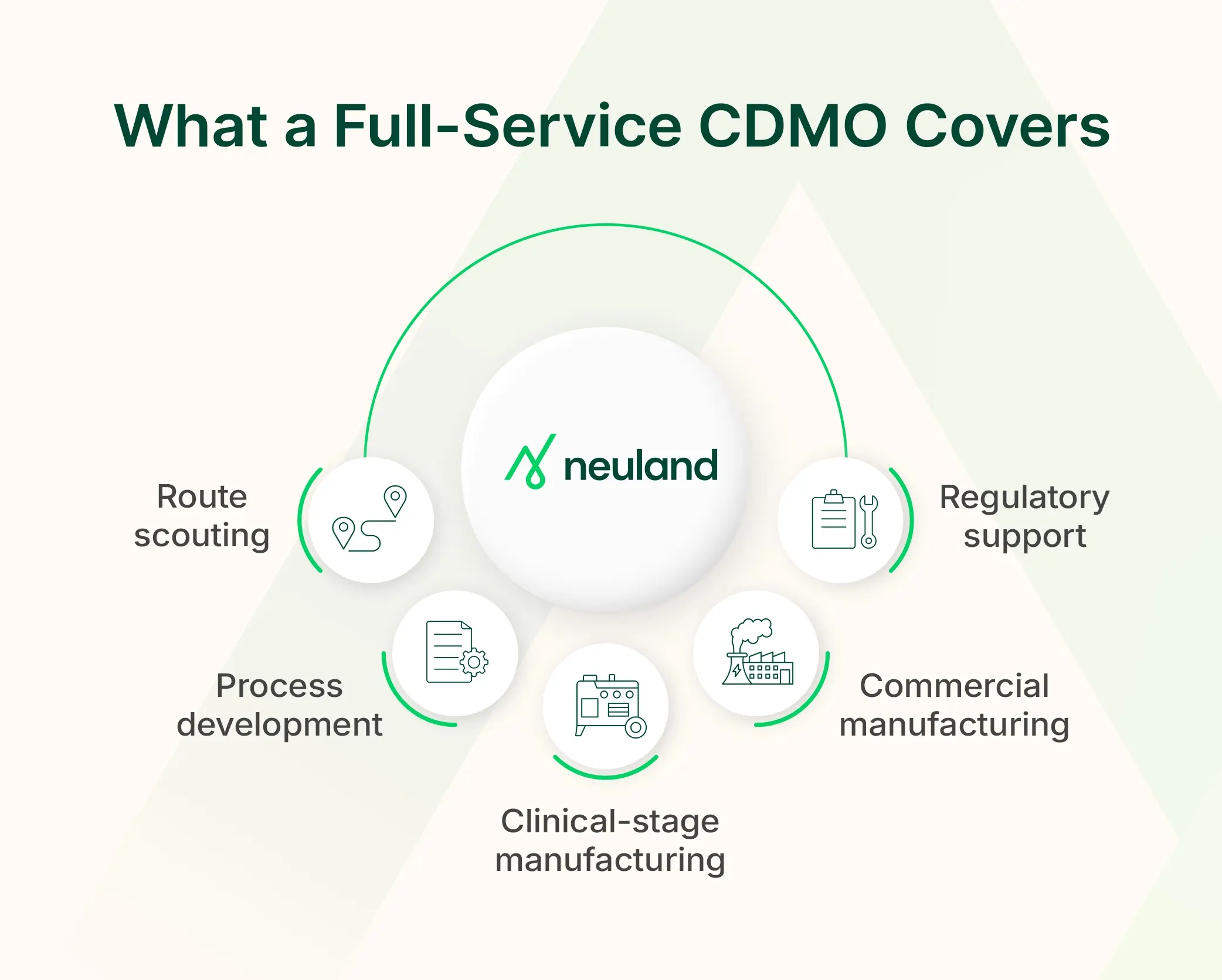

| What a Full-Service CDMO Covers | ||||

| Route scouting | Process development | Clinical-stage manufacturing | Regulatory support | Commercial manufacturing |

6 Key Benefits of Partnering with a CDMO

1. Speed to Market and Agility

Partnering with a CDMO can significantly accelerate your drug’s time to market. These organizations are equipped with established facilities, expert teams, and refined processes, allowing projects to ramp up quickly.

This speed advantage is crucial in today’s competitive environment, where getting to the clinic or market even a few months sooner can be a game-changer.

2. Scalability and Flexibility

You might need only grams of API for early trials, but metric tons upon commercialization. CDMOs are built to accommodate that growth.

They have large-scale reactors, production lines, and the engineering know-how to scale processes from lab bench to factory floor. This means you don’t have to invest in building a plant for a product that may succeed or risk one sitting idle if it fails.

Moreover, they bring flexibility in handling different molecules or dosage forms. If the demands suddenly spike, CDMOs such as Neuland Labs have the flexibility and capacity to scale up or scale down as per their requirements.

3. Regulatory Expertise and Quality Compliance

Top CDMOs employ regulatory affairs specialists and quality assurance teams intimately familiar with FDA, EMA, and ICH requirements and the latest compliance standards.

They design development and manufacturing processes in accordance with current Good Manufacturing Practices (cGMP) and can prepare the documentation needed for regulatory submissions. This ensures that the materials produced will meet the stringent criteria of regulators around the world.

Their experience with multiple regulatory inspections and audits can help smooth the approval process for your drug.

4. Access to Specialized Technology and Expertise

By partnering with a CDMO, you gain immediate access to capabilities that might otherwise take years and massive investment to build in-house.

For example, a CDMO might have proprietary cell culture bioreactors for biologics, or automated chemistry platforms for complex synthesis, as well as teams of scientists and engineers who are experts in those domains.

This enables higher yields, better process efficiencies, or novel drug delivery formats that can differentiate your product.

5. Cost Optimization Through Shared Infrastructure

One of the primary reasons firms turn to CDMOs is to reduce costs and optimize their use of resources.

Building and maintaining pharmaceutical manufacturing facilities, hiring and training specialized staff, and ensuring compliance can be enormously expensive. By outsourcing, companies convert these fixed costs into variable costs tied to the project’s needs.

A CDMO can achieve economies of scale by serving multiple clients, thus lowering the unit cost of production for everyone. Additionally, their experience often means fewer costly errors or inefficiencies.

6. Faster Global Market Entry and Supply Chain Reach

Many CDMOs have a global footprint with facilities or partnerships, which can help ensure supply on a worldwide scale.

This global knowledge means a CDMO can help tailor the development and manufacturing process to meet various market standards in parallel, speeding up international approvals and launch timelines.

Moreover, after the COVID-19 pandemic and other supply chain disruptions, companies are keen to diversify and de-risk their supply chains.

Working with a CDMO, such as Neuland Labs, with multiple manufacturing units adds resilience. With parallel capacity in place, supply can continue uninterrupted across markets.

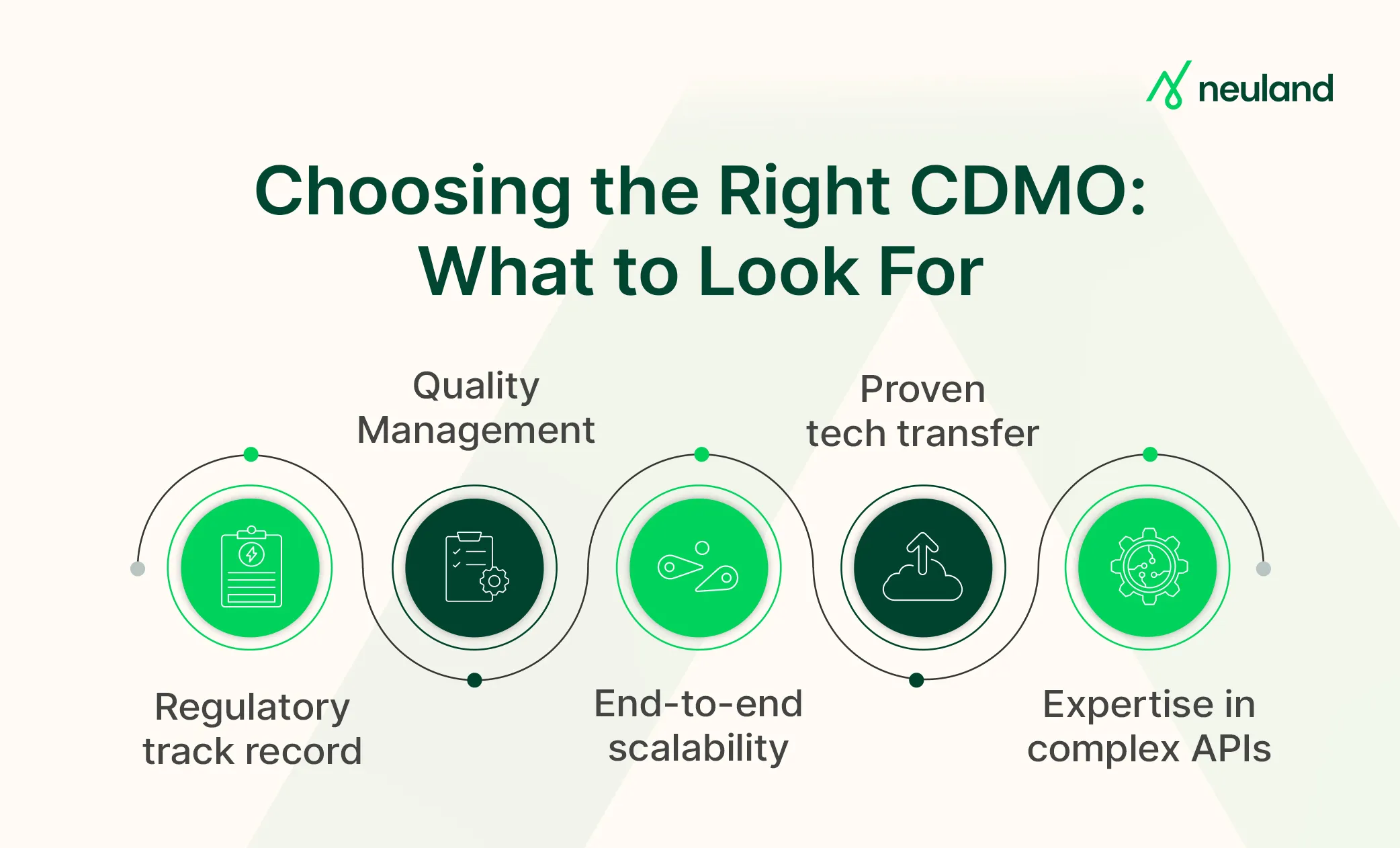

| Choosing the Right CDMO: What to Look For | ||||

| Regulatory track record | Quality Management | End-to-end scalability | Proven tech transfer | Expertise in complex APIs |

Trends Making CDMOs More Relevant Than Ever

Digital Transformation and Pharma 4.0

CDMOs are investing in “Pharma 4.0” capabilities to improve efficiency, quality, and transparency.

For example, many are implementing electronic batch records, real-time monitoring systems, and even AI for predictive process control. CDMOs embracing these tools can offer clients faster tech transfer, more consistent production, and better visibility into project status.

The net effect is that CDMOs with high digital maturity can deliver projects faster and with fewer errors, which is a compelling advantage for partners who choose them.

Evolving Regulatory Landscape

Lately, we’ve seen new guidelines emerge for novel therapies. For instance, authorities have been formulating specific GMP guidelines for cell and gene therapies, oligonucleotides, and peptide drugs.

Regulatory agencies are also raising the bar on data integrity, supply chain transparency, and quality standards.

CDMOs are often deeply engaged with these regulatory trends. They participate in industry forums, update protocols to meet new standards, and even help shape best practices.

They ensure that your drug development and manufacturing processes remain compliant amid changing rules.

Surge in Biologics, Peptides, and Specialized Therapies

The pharmaceutical pipeline has increasingly shifted towards more complex modalities, including biologics and niche molecules such as peptides and oligonucleotides.

CDMOs such as Neuland Labs have responded by expanding into dedicated peptide production labs.

Growth in areas like biosimilars, biologics, personalized medicines, and orphan drugs is boosting demand for CDMO services. The breadth of the CDMO industry today covers nearly every emerging modality.

Strategic Partnerships and Integrated Services

Rather than hiring a CDMO only for a single step, companies are increasingly looking for partners who can work across their entire pipeline and multiple projects.

The benefit of this model is seamless continuity and deep alignment between the company and the CDMO. It can reduce technology transfer times since the same partner carries the project from phase to phase.

This partnership model is reinforced by the trend of risk-sharing deals, where CDMOs might tie their success to the success of the client’s product, aligning incentives for speed and quality.

Choosing the Right CDMO to Realize These Benefits

CDMO partnerships aren’t just a workaround for missing infrastructure, they’re how serious pharma companies stay competitive. But not all CDMOs are built the same.

The right partner brings operational focus, regulatory foresight, and the ability to scale without surprises. Neuland Labs has done exactly that for over 40 years, developing 300+ APIs and supporting 500+ global clients with chemistry that doesn’t stall when the stakes are high.

If your molecule demands precision, reliability, and speed, we’re built for it. Let’s move it forward, together.

FAQs

|

|

|

|