Peptide Conjugation - Common Conjugation Strategies

Peptide therapeutics are small compared to protein-based therapies but represent a growing pharmaceutical market segment. With approximately 100 FDA-approved peptide therapeutics on the market, including blockbuster drugs like semaglutide, and hundreds more in preclinical and clinical development, interest in this class of molecules continues to rise.

Peptides, typically less than 50 amino acids (a key differentiator with protein therapeutics and other biologics), offer key pharmacologic advantages: small size, predictable metabolism, and high target specificity. Yet they face significant development challenges: They have a short half-life – on the order of minutes to hours – in the bloodstream and poor oral bioavailability.

To rectify these limitations, peptide conjugation has emerged as a powerful and proven approach. By covalently attaching non-biological or biological compounds to a peptide, developers can extend circulation time, reduce proteolytic degradation, and enhance tissue or cellular targeting.

In this blog, we’ll explore peptide conjugation strategies, highlight common modifications and techniques, and explain how Neuland Labs supports custom, scalable manufacturing of conjugated peptides.

What is Peptide Conjugation?

Peptide conjugation is a synthetic process that involves the covalent attachment of biological or synthetic chemical moieties to a peptide.

For peptide therapeutics, conjugation can focus on increasing drug-like characteristics (such as stability) or delivering a small-molecule drug to a specific tissue or cell type. The benefits of conjugation include extended half-life, protection against enzymatic degradation, and enhanced targeted delivery.

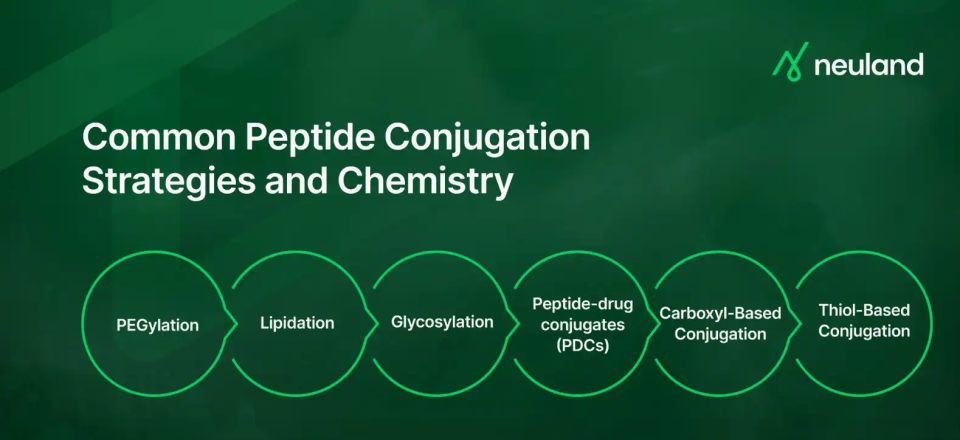

Common Peptide Conjugation Strategies and Chemistry

Common compounds conjugated to therapeutic peptides include polyethylene glycol (PEG), lipids, sugars, and other peptides or proteins. These can be attached to functional groups at the peptide’s N- or C-terminus or to internal residues like cysteine or lysine using various chemical methods. Conjugation strategies depend on the chemical group being attached and the required site specificity. Reactions must be selective, efficient, and biocompatible, preserving peptide function. The following section focuses on key conjugation moieties and methods.

PEGylation

PEG chains can be covalently attached to a peptide and offer several pharmacological advantages. PEGylation reduces proteolysis, immunogenicity, and filtration by the kidney, while increasing solubility. FDA-approved examples include Pegasys® and Neulasta®, where PEGylation was used to extend half-life and improve therapeutic efficacy.

Peptide PEGylation typically involves activation of PEG with a linker, then conjugating it to an amino, carboxyl, or thiol group. Conjugation to N-terminal amine or lysine side chains can be done using activated PEGs such as N-hydroxysuccinimide (NHS) esters. Alternatively, thiol-specific PEGylation can be performed using maleimide-activated PEGs, which react selectively with cysteine residues to form stable thioether bonds.

Lipidation

Peptide lipidation involves the covalent attachment of lipids, such as fatty acids or isoprenoids, to peptides. Resulting lipopeptides can have enhanced stability, bioavailability, and therapeutic efficacy. It can strengthen resistance to proteolysis, receptor binding, and membrane permeability, enabling intracellular delivery, while reducing kidney clearance. Levemir® is a long-acting insulin analogue with a C14 myristic acid attached to an internal lysine that increases half-life.

Lipid groups such as palmitic or myristic acid can be added during solid-phase peptide synthesis (SPPS) or in-solution synthesis using pre-lipidated amino acids or post-synthesis modification. Other methods include S-acylation (e.g., S-Palmitoylation), where lipids are linked to cysteine residues via thioester bonds using reagents like palmitoyl chloride or through “thiol-ene” reactions such as cystein lipidation on a peptide or amino acid (CLipPA). N-acylation (e.g., N-myristoylation) is another method that targets N-terminal amines or lysine side chains with activated fatty acids to form stable amide bonds.

Glycosylation

Attaching carbohydrate groups to peptides through glycosylation improves stability and bioavailability. Glycopeptides can have expanded biodistribution, enabling targeted delivery to specific tissues or cell types through receptor-mediated glycotargeting. Although no FDA-approved glycosylated peptide drugs are currently on the market, glycosylation remains a powerful strategy for optimizing therapeutic peptides.

There are two main strategies for glycosylating peptides: N- and O-linked glycosylation and N-terminal glycosylation. SPPS or in-solution synthesis is used to couple a pre-glycosylated amino acid within the peptide chain for N- and O-linked glycosylation. Fluorenylmethyloxycarbonyl (Fmoc), rather than tert-butyloxycarbonyl (Boc), chemistry is favored for this due to its mild conditions, which protect glycosidic bonds. N-terminal glycosylation is achieved using ethanoic acid modification or succinamic linker conjugation.

Peptide-drug conjugates (PDCs)

PDCs are an emerging class of targeted therapeutics that combine a targeting peptide, a linker, and a small-molecule drug. These conjugated peptides can selectively deliver drugs to diseased cells, such as tumors. Despite challenges like short half-life and low bioavailability, chemical modifications such as PEGylation, lipidation, glycosylation, or cyclization have enhanced stability, selectivity, and drug delivery. FDA-approved examples, like Lutathera®, highlight the clinical promise of PDCs, which are also being explored for non-cancer indications, including COVID-19 and autoimmune diseases.

The most common chemical strategies for generating PDCs are click reactions, such as copper-catalyzed azide–alkyne cycloaddition (CuAAC). Azide or alkyne groups can be easily introduced to a peptide during SPPS or in-solution synthesis. Thiol-based chemistries are also used for conjugation to cysteine residues. Chemical conjugation methods are selected based on the selectivity, stability, and compatibility with the peptide’s structure and therapeutic application. The conjugation method is also determined by the linker chemistry and whether it’s cleavable, non-cleavable, or pH sensitive.

Other Common Peptide Conjugation Chemistry

Carboxyl-Based Conjugation

Carboxylic acids, present at either the C-terminus of a peptide or on the side chains of aspartic and glutamic acid residues, are also reactive groups that can accommodate conjugation. They are reactive to carbodiimides, and reagents like EDC ((1-ethyl-3-(3-dimethylaminopropyl)carbodiimide)) and EDC/NHS combinations are used to conjugate peptides to proteins or other carriers via carboxyl-to-amine crosslinking.

Because there are multiple carboxyl and amine groups in peptides and proteins, carboxyl-to-amine crosslinking often occurs non-specifically. The reaction is also pH-sensitive, with less efficient reaction chemistry at neutral pHs.

Thiol-Based Conjugation

Sulfhydryl groups in the side chain of cysteine are another reactive group for efficient peptide conjugation. As mentioned above, it's used to generate PDCs or PEGylated peptides. Sulfhydryl groups can react with maleimides, haloacetyls, and pyridyl disulfides, making them precise, efficient, and perfect for site-specific conjugation.

Navigating Peptide Conjugation with Neuland Labs

Peptide conjugation expands the therapeutic potential of peptides by enhancing their drug-like properties. From PEGylation to drug conjugates, these strategies address key development challenges and open new avenues in drug design.

Neuland Labs can help your peptide development team choose a peptide conjugation strategy and navigate process development for scalable peptide manufacturing. We support peptide synthesis from 5 to 60 amino acids using SPPS, in-solution synthesis for shorter peptides, and segment condensation or ligation methods for peptides up to 120 amino acids.

Contact us to learn more about how we can support your process development & optimization, large-scale GMP manufacturing, and analytical development and validation.