ESG in Pharma: How CDMOs Drive Sustainable Supply Chains

The pharmaceutical industry is under intense pressure to integrate ESG in pharma into every step of its operations. ESG stands for Environmental, Social, and Governance criteria, each of which is an indispensable component today.

The industry’s direct operations emit 52 megatons of CO2 annually, and this includes the indirect supply chain emissions. As a result, most large drug makers are publicly committing to cut carbon, waste, and water use, and to source more sustainably.

Companies seeking a sustainable pharmaceutical supply chain now demand that their contract development and manufacturing organizations (CDMOs) adopt greener practices at every stage. Let’s understand how CDMOs drive sustainability via their supply chains in detail.

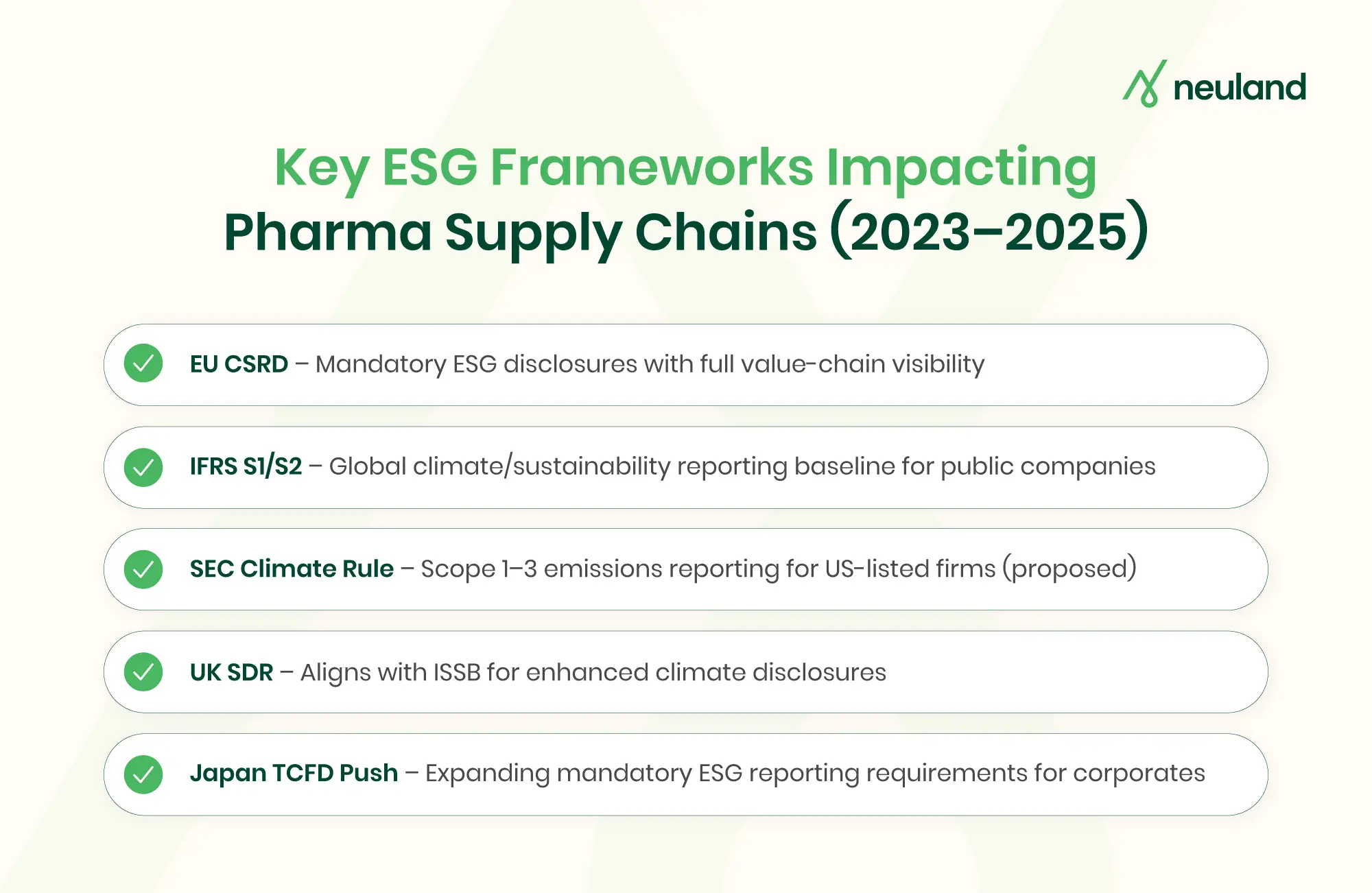

1. Global ESG Reporting Standards and Regulations

New regulations and frameworks are reinforcing this trend. For example, the EU’s Corporate Sustainability Reporting Directive (CSRD), effective 2024, mandates detailed ESG disclosures by pharma companies (and their suppliers), including material impacts throughout the upstream and downstream value chain.

Sector-specific standards for pharmaceuticals and biotechnology are being drafted under the CSRD, which will impose additional industry‑tailored ESG in pharma.

Likewise, the International Sustainability Standards Board (ISSB) issued IFRS S1 and S2 in mid‑2023 to require climate and other sustainability disclosures in financial filings. These rigorous frameworks force pharma companies to measure and report greenhouse gases (Scopes 1–3), water use, pollution, social impacts, and governance practices.

In practice, this means every link in the supply chain must be audited for ESG in the pharmaceutical industry.

2. Green Chemistry and Low-Carbon Manufacturing

CDMOs are answering the call with green manufacturing innovations. Leading facilities now use green chemistry in pharmaceutical manufacturing to drastically cut waste and emissions.

Continuous-flow reactors and biocatalytic processes are also growing. Such CDMO solutions not only improve yield and scalability but also simplify waste treatment.

CDMOs are also investing in clean energy and process efficiency. Compact Process Analytical Technology (PAT) and AI-driven design tools further optimize reaction conditions to reduce energy use and solvent waste. Together, these measures make pharma production more eco‑efficient while meeting quality and safety requirements.

3. Sustainable Clinical and Commercial Supply Chains

Beyond production, CDMOs are streamlining supply chains for lower impact. Logistics – especially for clinical trial materials – can add significant carbon.

Contract service providers report that over 70% of life‑sciences emissions originate in the supply chain (Scope 3). To tackle this, CDMOs optimize shipping routes, consolidate shipments, and even localize packaging.

This avoids extra air miles and refrigerants for cold chain transport, cutting the carbon footprint of clinical and commercial shipments.

Other tactics include shifting from single‑use shipping materials to recyclable or reusable containers, and using light-weight or bio-based packaging for ESG in pharma.

For example, firms are replacing hard plastic trays and insulation with paperboard, recycled plastics, or biodegradable polymers. Digital inventory tools (like IoT trackers and AI planning) help right‑size production and distribution, so fewer batches are thrown out or rerouted.

All of these sustainable pharma supply chain measures are now demanded by brand owners.

4. Ethical Sourcing, Packaging, and Circularity

Sustainability also covers raw materials and waste. CDMOs enforce strict supplier standards.

Neuland Labs, for instance, evaluates 100% of its Tier 1 suppliers on compliance with environmental management (ISO 14001) and social rules (no child labor, fair wages, etc.).

This ensures ethically sourced starting materials and avoids reputational risk. In procurement, many CDMOs use verified chemical databases and EcoVadis-type assessments to vet suppliers for green credentials.

By using lighter materials, bulk packaging, and PVC-free films, waste per dose is plummeting. Several CDMOs now offer all-paper corrugated totes and reusable shippers for clinical trials. These practices of ESG in pharma, from solvent recovery and wastewater recycling to pharmaceutical take‑back programs, embody circular economy principles.

Infographic 2:

Title: Green Chemistry Innovations in Pharma Manufacturing

5. Governance and Social Responsibility

CDMOs maintain rigorous compliance systems (cGMP, anti-bribery policies, corporate governance) that protect ethical standards. They also implement workplace safety, employee health, and community programs as part of their ESG agenda.

For instance, Neuland Labs is committed to global sustainability goals. It is a member of the UN Global Compact (renewed in 2023) and aligns its corporate strategy to the UN Sustainable Development Goals.

By embedding these social and governance norms – such as third-party audits, diversity initiatives, and community engagement – CDMOs help customers meet investor and regulatory expectations of ESG in pharma.

Neuland Labs: Leading the Sustainable CDMO Charge

In summary, ESG in pharma means overhauling both clinical and commercial supply chains – and CDMOs are on the front lines. Neuland Labs exemplifies this shift.

Our supply‑chain framework explicitly ties ESG principles to growth and risk management. Neuland has even launched a dedicated supplier‑engagement program called NeuACTS: Neuland Advancing Collaboration Towards Sustainability.

These efforts, along with Neuland’s commitment to renewable energy and science‑based targets, demonstrate how a leading CDMO company is turning ESG into an opportunity.

By investing in green chemistry, ethical sourcing, and low‑carbon operations, Neuland and its peers are now enabling a sustainable pharma supply chain that benefits patients, customers, and the planet alike. Get in touch today to future-proof your supply chain with a sustainability-led CDMO.

FAQs

|

|

|

|