Sustainability has become a key trend in drug manufacturing. As we’ve previously discussed (here and here), this is being driven by environmental/good corporate stewardship efforts as well as various cost considerations. From greening supply chains to reductions in carbon emissions, pharmaceutical companies are increasingly taking steps to incorporate the principles of green chemistry into every aspect of their business.

Sustainability has become a key trend in drug manufacturing. As we’ve previously discussed (here and here), this is being driven by environmental/good corporate stewardship efforts as well as various cost considerations. From greening supply chains to reductions in carbon emissions, pharmaceutical companies are increasingly taking steps to incorporate the principles of green chemistry into every aspect of their business.

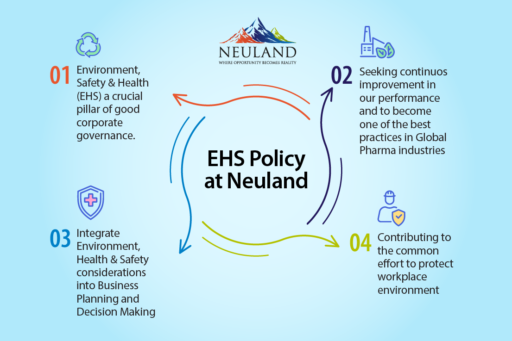

With organizational spotlights focused on sustainable practices, Environment, Health, and Safety (EHS) departments are receiving a great deal of attention.

The Challenging Role of an EHS Department

Although ecological responsibility and sustainability are popular buzzwords today, EHS teams don’t have an easy job. Much of pharma’s success, in fact, rests on the EHS department. From a ‘green business’ perspective, the department is responsible for developing and implementing policies that encourage sustainable practices throughout an organization. They also monitor the progress of those efforts.

From a ‘green chemistry’ perspective, they work closely with process and product chemists to ensure the safety of manufacturing processes. Without a competent team, the safety of the workplace, the employees, and the environment is at risk.

Effective EHS policies keep operations running smoothly toward the goal of sustainability, ultimately creating a healthy balance between risk mitigation and adherence to sustainable green principles.

EHS and Continuous Improvement

Even as EHS teams achieve successes and make strides in supporting sustainability, they remain aware that their work isn’t once-and done. Rather, it is an ongoing process focused on continuous improvement. Key functions of EHS team members include evaluating processes and practices, focusing on employee education through green training and setting measurable goals for green actions.

EHS Focus on Employee Health

To prioritize occupational health, an EHS team should offer training that covers personal hygiene, health monitoring, first aid knowledge, and adherence to COVID protocols. These health-related issues recognize the importance of human workers and are indispensable to the protection of company manpower. Many pharmaceutical companies are still rebounding from the detrimental effects of COVID-19 on the workforce. Protective measures that preserve employee health are crucial.

Additional EHS training that focuses on other areas of concern – such as chemical safety and emergency procedure – are also vital. The success of the safety-based employee education is often evidenced by a reduction in the number of negative incidents and failed audits that occur.

Teams can monitor and facilitate company sustainability through:

Teams can monitor and facilitate company sustainability through:

- Routine site inspections. The goal is to identify safety concerns and rectify them quickly. The EHS department should offer one-on-one guidance when necessary, giving staff members as much assistance as they need to master safer techniques.

- Facility design reviews. As renovations are needed and layouts are planned, EHS experts recommend changes that adhere to safe practices supporting both employee and ecological health.

- Emergency drills. Drills can be used to expose employees to mock emergencies and help them prepare for the unexpected.

- Incident investigations. Once an incident occurs, teams should be prepared to lead an investigation to determine the root cause. Additionally, they must ensure the implementation of corrective and preventive actions to avoid a recurrence.

Drug Manufacturing Sustainability Practices

The sustainability practices EHS teams employ are largely directed towards the reduction of waste output. Below are additional practices that EHS teams use to promote sustainability:

- Reduction in solvent usage. EHS experts are identifying less-harmful alternatives to traditional solvents.

- Recycling of materials. By reusing materials, companies can reduce their environmental impact.

- Reduction in the use of natural resources. EHS departments advocate the conservation of natural resources.

Despite the challenges associated with greener API manufacturing, some drug API manufacturers – including Neuland Labs – are leveraging better synthetic route design and sourcing alternate chemicals, reagents or precursors. The results can include less effluent and pollution, higher yields, shorter processing times, the use and storage of lower volumes of volatile chemicals, and the ability to downsize manufacturing infrastructure.

EHS, Sustainability & Neuland Labs

All of Neuland’s manufacturing units have adopted policies that protect the environment – including climate change and energy policies to reduce the company’s carbon footprint and Zero Waste Discharge policies to help minimize waste to landfills.

One key aspect of sustainable chemistry focuses on minimizing waste disposal via incineration. Working towards a goal of 0% incineration of waste, we send our spent solvent and other material waste to cement manufacturers, who use co-processing technology to convert this waste to an auxiliary fuel.

We achieved a recovery rate of 80-85% in FY 2021 using sophisticated solvent recovery systems. A wastewater treatment plant with higher capacity also came online, enabling the efficient management of additional load on the effluent system due to operational surges.

Some of the additional changes we’ve implemented are:

- ISO 14001:2015 and ISO 45001:2018 certifications for all manufacturing units.

- Recycling of treated water. Neuland’s recycling efforts employ good water accounting to conserve water and reduce waste.

- Control of emissions. Scrubbers are used to improve air quality – reducing emissions and ensuring that they stay well below restricted levels.

- Management of hazardous waste. The collection, storage, transport, and disposal of the waste are governed by strict guidelines that adhere to regulatory standards of Hazardous Waste Management Rules, 2016.

- Water runoff storage.

- Specialized liquid chemical storage.

By assuming global good stewardship practices and incorporating EHS-focused actions, the pharmaceutical industry is well-positioned to optimize opportunities to protect the world’s citizens and ecological systems.

Related Blog Content

EHS Stewardship: Green Chemistry, Healthy People, Healthy Workplace

Green Generic Drug Substances: Increased Upfront Costs Offset by Long-Term Profitability

API Production: Building a Process Safety Culture

Resources

Learn more about Neuland’s Environmental, Health and Safety (EHS) Team.

Learn about Corporate Social Responsibility at Neuland Labs.