Earlier this year, Neuland began working with a technology called Molecular HivingTM along with Jitsubo Co. (Read the March 2018 press release here). It’s a patented technique to manufacture peptides with innovative TAG-assisted liquid phase peptide synthesis (LPPS), and delivers high-quality & low-cost peptide APIswith short lead times.

Earlier this year, Neuland began working with a technology called Molecular HivingTM along with Jitsubo Co. (Read the March 2018 press release here). It’s a patented technique to manufacture peptides with innovative TAG-assisted liquid phase peptide synthesis (LPPS), and delivers high-quality & low-cost peptide APIswith short lead times.

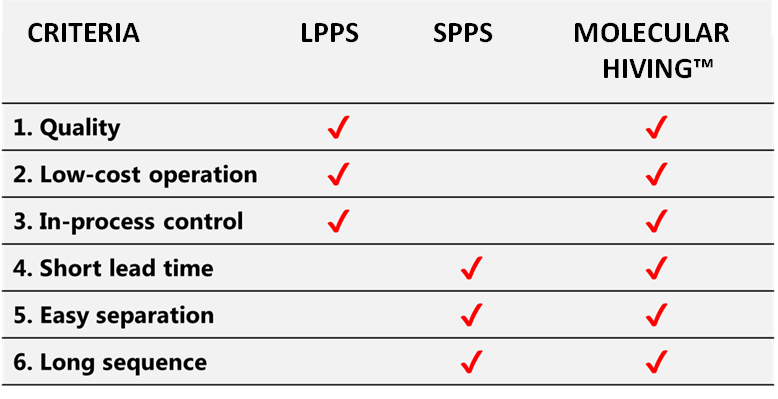

Molecular HivingTM – developed by Neuland’s collaboration partner Jitsubo Co. (Yokohama, Japan) – is a manufacturing scale technique which offers tremendous cost advantages over traditional methods, whether LPPS or SPPS (Solid Phase Peptide Synthesis).

Molecular HivingTM – Combining the Benefits LPPS & SPPS

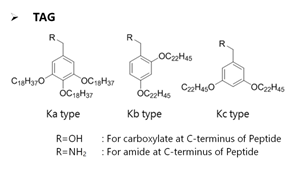

The technique uses TAG, hydrophobic benzyl alcohol or benzyl amine derivatives at C-terminus – instead of resins in solid phase synthesis (SPPS). The reactions of coupling to form peptides and deprotection of N-Fmoc or Boc in slightly hydrophilic solvent are performed in homogeneous solution (typical of LPPS).

Precipitation and isolation of a desired tagged-peptide is easily performed by adding a hydrophilic solvent to the reaction mixture.

Molecular Hiving: How it Works

Molecular Hiving: How it Works

By using its patent-protected achiral hydrophobic tags, peptide solubility can be controlled. A synthesis begins with the attachment of a patented hydrophobic tag to the C-terminal amino acid.

Peptide chemistry reactions are then performed in a hydrophobic solvent. When the reaction is complete, the tagged peptides can be precipitated and filtered.

The process effectively removes excess reagents present in the reaction mixture, providing high yields of high purity peptides.

Peptide APIs: Benefits of Molecular HivingTM

This peptide synthesis technology achieves the key advantages offered by both of the standard peptide manufacturing techniques – solid phase peptide synthesis (SPPS) and liquid phase peptide synthesis (LPPS). Molecular HivingTM offers a potential range of benefits, including:

- Highly efficient synthesis without the use of excess raw materials.

- High-purity peptides can be manufactured due to process monitoring.

- Minimized loss during downstream processing due to high-purities obtained upstream.

- Combination of LPPS benefits (quality, cost efficiency & process control) with SPPS benefits (short lead times and long sequence capabilities).

- High reactivity during synthesis, allowing for easy isolation of the targeted peptide during work-up.

- Fast process, allowing for shorter lead times. Reaction times, for example, are very short, and operation steps can be completed in 1-2 hours.

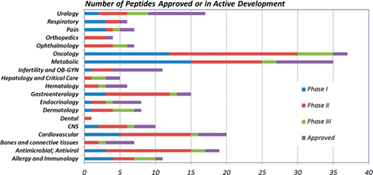

Growing Opportunities for Peptide APIs.

Growing Opportunities for Peptide APIs.

New technologies such as Molecular HivingTM will play an important role in helping to deliver on the promise of the peptide class of therapeutics. Anything that can move to needle on cost – a key challenge with therapeutic peptide APIs – should be considered a very exciting technology. The promise of high-quality-while-affordable peptides is a key reason why the Jitsubo technology is potentially a key manufacturing differentiator.

From Neuland’s standpoint, the potential to bring together Jitsubo’s Molecular HivingTM technology with Neuland’s specialized purification technology and peptide capabilities is very exciting. We see this research and development collaboration in the field of peptides as a way to complement our strength in peptide manufacturing (Solid, Solution and Hybrid phase) & our own proprietary purification technology with an innovative – and commercially cost-effective – technology.

Want to learn more about complex peptide manufacturing? Contact Neuland today.