A pharmaceutical manufacturer is only as good as its supply chain. Supply chain management and strategic sourcing are the key drivers which keep operations running smoothly.

Set the Right Inventory Targets

When planning for the coming quarter, you need to ensure capacities are fully met. Adequate inventory of required items and at right quantities ensures continuous production thereby exploiting capacities to the maximum.

An OTIF – or ‘On Time in Full’ – calculation with a target of 95% is measured against pre-agreed benchmark lead-times. Here at Neuland we treat all User Departments requesting consumables as internal customers. Against agreed timelines, timeliness of deliveries is measured based on which all OTIF calculations are recorded. To achieve a high OTIF score means to balance the cost of disservice with the cost of carrying more inventories.

Choose Pharma Supplier Sources with Care

It is critical to identify reliable sources that meet all aspects of your company’s requirements. When qualifying API supplier sources, consider among others:

- Route of synthesis

- Regulatory standing

- Scalability

- Cost-efficient processes

At each stage of the process, look for sources who meet your expectations for the supply of drug intermediates and key starting materials (KSM) for new products.

Line Up Multiple Sources

Once you’ve determined how to seek out and qualify your sources, you can use that same process to secure as many sources as possible for each KSM.

Remember, sources can suddenly be disqualified or lost without warning due to unforeseen issues—anything from pollution to business viability to regulatory issues or other problems which might prompt closures or supply chain constraints. While being caught in a single-source situation may be unavoidable (due to specific expertise or infrastructure), new alternate suppliers should be continuously sought and added to your source base. The more trusted sources you can enlist, the more your company’s reputation (or reliability) is potentially safeguarded.

Aim High, with First Time Right Approach

With the goal of continuous improvement, employ a First Time Right (FTR) approach. The FTR thinking focuses on suppliers and helping them to avoid potential rejections – internally though, it aims to focus and attack wherever gaps exist in specifications, methods and analyses. Striking a balance between supplier focus and internal accountability, such an approach can extend to everything from alignment of test methods including HPLC/GC columns and release procedures to pre-shipment clearance of CoAs. It can also be used to verify the recentness of production batches with select Suppliers of your KSM and Intermediates, to confirm the quality of incoming materials is in line with expectations.

Ensure Regulatory Compliance of the Supplier Base

A compliance program designed for KSM and Intermediate Suppliers can keep your supplier base audit-ready. Such a program should emphasize traceability, and clearly demonstrate that all processes are performed in compliance with relevant regulatory standards and the quality agreements made with Suppliers.

Boost Performance

To improve supplier performance on commercial and technical parameters, you can measure and score:

- Supply competitiveness

- Supply quality

- Documentation support

- Compliance

- Speed of supplier response

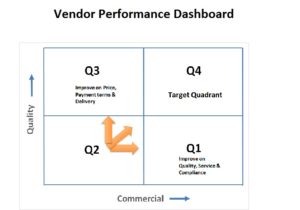

All of these can be measured on an objective pre-determined scale, plotting supply base performance on two different axes of a Supplier Performance Dashboard. From there, Supplier Improvement Actions can be devised with the goal of moving the suppliers from three different sub-optimal quadrants (Q1, Q2 and Q3) to a more desirable fourth quadrant (Q4) [see image, at right].

All of these can be measured on an objective pre-determined scale, plotting supply base performance on two different axes of a Supplier Performance Dashboard. From there, Supplier Improvement Actions can be devised with the goal of moving the suppliers from three different sub-optimal quadrants (Q1, Q2 and Q3) to a more desirable fourth quadrant (Q4) [see image, at right].

Check Competitiveness

Buying competitiveness can be measured using relevant benchmarks. Via a transparent RFQ process, you can invite multiple quotes, and then fine-tune the results based on Commodity Price Trends.

Deliver On Time

A manual tracking program can be used to track outbound cargo from origin to destination, per delivery terms. The Outbound Delivery OTIF, which is an effectiveness metric, (at Neuland, the target is >=95%) should reflect successful delivery lead-times vis-à-vis pre-determined target lead-times taking into account mode of transport and destination. Good performance in OTIF is a key indicator (barometer) of an end-to-end supply chain that’s working effectively.

By effectively pursuing and gaining visibility of demand to plan inventory, choosing and guiding sources that meet your expectations for quality, and keeping everything on track with an OTIF that makes sense for your business, you can manage your supply chain and sources with greater efficiency – improving your bottom line and benefiting your customers.