April 22 is Earth Day and this year’s theme is Restore our Earth. On their website, Earthday.org states “When life around the globe returns to normal, our world cannot return to business-as-usual.”

April 22 is Earth Day and this year’s theme is Restore our Earth. On their website, Earthday.org states “When life around the globe returns to normal, our world cannot return to business-as-usual.”

It’s a powerful message indicating we stand at a crossroads, with different choices available to us on how we reestablish our lives. Do we pick up where we left off in 2019, ignoring 2020? Or do we use this opportunity to re-invent ourselves, our businesses and our communities?

Within the pharmaceutical and biopharmaceutical industries, 2020 has – indeed – caused a rethink of ‘business as usual.’

We’ve seen this across multiple fronts – from never-before-seen levels of collaboration to comprehensive reevaluations of supply chains. We’ve written on both topics – with the former (global collaboration in the fight against SARS-CoV-2) an unheralded, remarkable achievement, and the latter (the elevation of supply chain concerns) all too predictable, in light of worrisome events & trends over the last decade or so.

In the spirit of Earth Day, another ‘rethink’ is warranted. This one doesn’t come out of the blue, but – like supply chains – has slowly (but inevitably) crept into the industry’s consciousness: green chemistry.

Green Chemistry and the Pharma Industry

Green chemistry (‘sustainable chemistry’) concentrates on chemical processes which reduce or (preferably) eliminate entirely the use of hazardous chemicals and reagents, along with the waste they create. Drug manufacturing waste management and pollution control involves a significant amount of technology and infrastructure, such as multi-effect evaporators, vertical thin film dryers and reverse osmosis facilities.

The global pharma industry – like many others – has historically suffered from waste and pollution problems. Even today, drug manufacturing waste generation remains largely unregulated. (At Neuland, our EHS department is tasked with working on exciting initiatives aimed at reducing our ecological footprint – and customer costs.)

Different countries have addressed (or not) this issue in different ways, though it is by no means a problem that has been solved anywhere around the world. Regulations have emerged to mitigate the challenges (again, with different countries and regions doing more – or less). Industry-driven initiatives such as green chemistry and zero liquid discharge (a closed-loop cycle that minimizes or eliminates discharge of any liquid effluent by recycling and treating all wastewater), however, may hold the true keys to more sustainable drug production – driven by business decision-making, rather than via regulation…a change process which ultimately tends to be more effective.

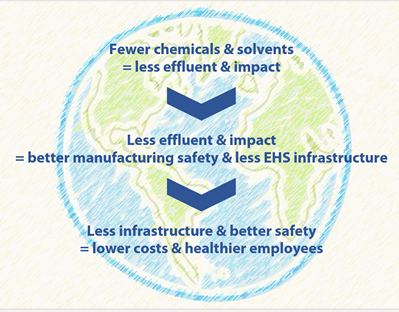

Among pharma, green chemistry has never been particularly trendy, but for those drug manufacturers who have paid attention it is important. In fact, setting aside its earth-friendly, ‘Go Green!’ attributes, it just makes good business sense.

Why?

Green chemistry can save companies money. Here are some of the economic and business advantages green chemistry offers, according to the U.S. Environmental Protection Agency (EPA):

Green chemistry can save companies money. Here are some of the economic and business advantages green chemistry offers, according to the U.S. Environmental Protection Agency (EPA):

- Higher yields for chemical reactions, consuming smaller amounts of feedstock to obtain the same amount of product

- Fewer synthetic steps, often allowing faster manufacturing of products, increasing plant capacity, and saving energy and water

- Reduced waste, eliminating costly remediation, hazardous waste disposal, and end-of-the-pipe treatments

- Better performance so that less product is needed to achieve the same function

- Reduced use of petroleum products, slowing their depletion and avoiding their hazards and price fluctuations

- Reduced manufacturing plant size or footprint through increased throughput

- Improved competitiveness of chemical manufacturers and their customers

We discussed some of the green chemistry practices we apply in a post back in 2014:

“At Neuland, we optimize input materials such as chemicals, solvents, fresh water as well as energy and process conditions in order to minimize environmental impact and health and safety hazards. For example, once an API production process has been developed, we then carry out process improvement initiatives to further maximize efficiency and reduce the impact of waste. All of our treated effluents are recycled to achieve Zero Liquid Discharge status.”

The fact is, green chemistry is not only good for the planet (and ultimately human health), but it is also good for the industry’s bottom line.

It is our obligation to recognize that we – as an industry and as individuals – can do better. That we must do better – for our health, for our communities and for humankind.

It is our obligation to recognize that we – as an industry and as individuals – can do better. That we must do better – for our health, for our communities and for humankind.

Got anything planned for Earth Day 2021? Head on over to our Facebook page and share!

Did you know? > More than 1 billion people now participate in Earth Day activities each year, making it the largest civic observance in the world. Learn more at earthday.org.