Soluble drug APIs are now the exception, not the rule.

An article at PharmTech by Felicity Thomas (Looking Beyond the Solubility Horizon) caught my eye recently as it discussed a pharma (and biopharma) industry trend that’s on the rise. Insoluble drug compounds now comprise nearly three-quarters of all new NCEs – potentially compromising bioavailability…and thus their value as therapeutics.

An article at PharmTech by Felicity Thomas (Looking Beyond the Solubility Horizon) caught my eye recently as it discussed a pharma (and biopharma) industry trend that’s on the rise. Insoluble drug compounds now comprise nearly three-quarters of all new NCEs – potentially compromising bioavailability…and thus their value as therapeutics.

Fact is, very few of our customers are able to dismiss solubility concerns outright. While solubility challenges seem to exist on something of a spectrum – with some drug solubility issues much easier to resolve than others – nearly everyone sees concerns arise during development.

Why the upsurge? According to the article, it “is a trend that is anticipated to continue to grow as a result of the industry drive toward development of more molecularly complex chemical entities.”

Our team concurs: the overall complexity of molecules, along with their increasingly hydrophobic character, has led to increased obstacles that must be overcome during process development. It’s a challenge that continues through to formulation development and beyond.

‘Making the Insoluble Soluble’

The PharmTech article shares some of the physical techniques used to overcome insolubility – namely, particle size reduction – when chemical synthesis techniques or the use of specific excipients is not practical or effective.

Chemical modifications during the development & scaling of an API can seem straightforward (replacing or changing the concentration of an ingredient, or buffer & pH changes). Unfortunately, even the smallest changes can have significant repercussions in terms of pharmacodynamics and pharmacokinetics – rendering it often a less-than-ideal technique.

Chemical modifications during the development & scaling of an API can seem straightforward (replacing or changing the concentration of an ingredient, or buffer & pH changes). Unfortunately, even the smallest changes can have significant repercussions in terms of pharmacodynamics and pharmacokinetics – rendering it often a less-than-ideal technique.

The preferred technique today for APIs is to physically modify the molecule – typically through milling (particle reduction). There are a number of different milling techniques, and each one has advantages and disadvantages. Much, of course, depending on the nature of the compound, its sensitivity to various forces (e.g., sheer or heat), and how successful a basic technique such as crystallization may be.

This topic was also discussed in a recent article at Drug Development & Delivery (Improving Bioavailability & Solubility: Chemical & Physical Modification vs. Formulation Development):

“Functional lipids are a versatile tool for formulators and offer delivery strategies like self-emulsifying drug delivery systems (SEDDS) and lipid nanoparticles (LNPs). Nanoemulsions (SEDDS, SMEDDS, SNEDDS) were developed to provide improved bioavailability, reproducibility, and enhanced API permeation.”

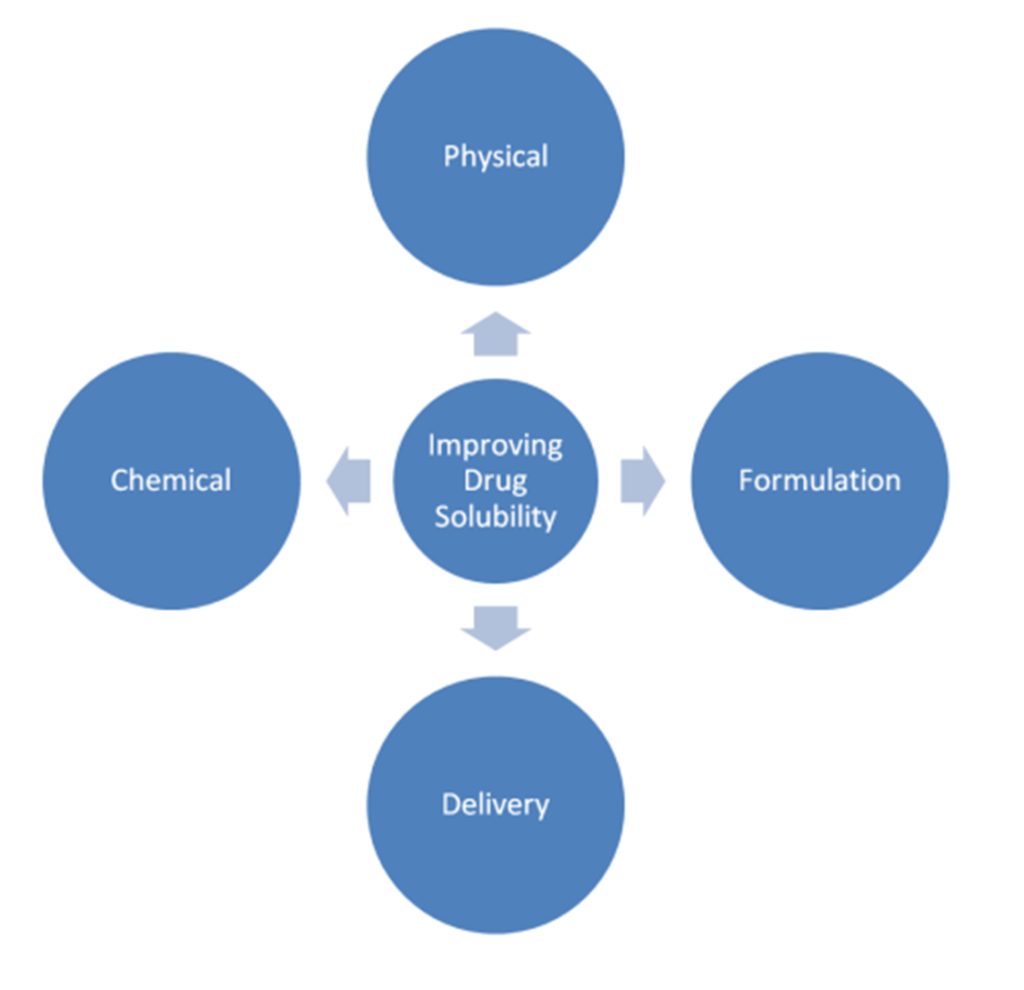

One conclusion of the article – “While physical and formulation strategies can individually increase bioavailability of molecules, a combinatorial approach may be the best” – perhaps best captures the increased complexity this issue poses to industry, and the need for increasingly complex – and multifaceted – solutions.

Neuland is no stranger to solubility challenges. Our NCE customers are seeing this issue emerge much more frequently than in decades past given the types of molecules we are developing. For this reason, we launched our PEL, or Process Engineering Lab (here’s a post on our PEL’s success stories with particle reduction). The PEL is well-suited to tackling particle engineering studies to resolve drug intermediate solubility issues.

Neuland is no stranger to solubility challenges. Our NCE customers are seeing this issue emerge much more frequently than in decades past given the types of molecules we are developing. For this reason, we launched our PEL, or Process Engineering Lab (here’s a post on our PEL’s success stories with particle reduction). The PEL is well-suited to tackling particle engineering studies to resolve drug intermediate solubility issues.

And while we have had success via route selection or process modifications, we often find one of the various types of milling (e.g., jet milling or multi-milling) is a good option to optimize API solubility.

The advent of so many different techniques to address solubility, however, can make a combinatorial – and cross-functional (chemical, physical, formulation and/or delivery) – approach ideal. Dr. Bowers in the Drug Development & Delivery article sums it up best:

Does your company have questions about API development & solubility?

We’re here to help! Contact Us Today >