An article at Pharma Manufacturing (Shrinking Big Pharma) pointed to the recent movement among Big Pharma towards smaller production floors.

It comes as no surprise.

With the rise of target-based drug discovery, the era of the blockbuster drug is fading – being replaced by a growing need for smaller, more nimble production units that can better address today’s need for lower-volume (and increasingly niche) therapeutics.

In 2014, the New York Times reported: “Seventy percent of new drugs approved by the F.D.A. last year were so-called specialty drugs used by no more than 1 percent of the population.”

The years between the launch of the first blockbuster (SmithKline Beecham’s Tagamet, in 1993) and the present have seen many new drugs reach blockbuster status.

The wider adoption of generics is also having an impact on the long-term ‘blockbuster’ potential of drugs. Drugs are losing sales to generics faster than ever today.

The wider adoption of generics is also having an impact on the long-term ‘blockbuster’ potential of drugs. Drugs are losing sales to generics faster than ever today.

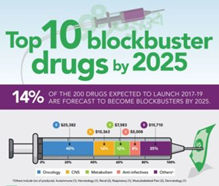

In spite of the rise of targeted therapies & generics, many drugs are still projected to become blockbusters. According to DRG: “about 200 launches are expected during 2017-2019, of which approximately 14% are forecast to become blockbusters.”

Shifting Drug Manufacturing Approaches

With that being said, pharma firms are recognizing there’s a shift towards precision medicine – and they are modifying their approach to drug manufacturing accordingly.

There are a number of reasons why companies are rethinking their manufacturing facilities and shrinking their production footprints. Here are several of the top reasons behind the shift towards smaller production blocks:

- Cleanrooms: Cost per Square Foot

Larger production blocks tend to be…well… This means more cleaning, which translates to additional manpower, equipment, consumables and time. In aseptic processing environments, the larger the space – the more surfaces there are to maintain…and the higher the costs. - Decreasing Demand for High Volume Drugs

As the industry focus shifts towards smaller-volume personalized drugs, Big Pharma needs to up their flexibility – allowing them to adapt to both blockbusters and niche therapies. - Smaller, More Flexible Manufacturing

Cutting edge production suites get more production out of less space, with the flexibility to repurpose the space as needed. As the article notes, companies are “looking for and successfully finding ways to make manufacturing more compact, flexible and mobile.” - Equipment Diversification

This is an issue which touches many industries, beyond the scope of pharma or biopharma manufacturing. At some point, firms begin to see the value of multiple smaller systems rather than one single massive production line. It permits scalability, and ultimately decreases system complexity and downtime.

These considerations have been S.O.P. among many contract manufacturers for quite a while. Since firms such as Neuland tend to work with a broad array of products – from orphan up to blockbuster-sized drugs – offering a diverse range of flexible production blocks has proven critical to our success and growth.