When your company decides to work with a CMO or CDMO on a drug API manufacturing project, the depth of the onboarding process dictates the success of the project. Onboarding is more than just signing a proposal and being introduced to the team. It’s a multi-faceted process that ensures everyone has done their due diligence and considered all of the project’s various components.

When your company decides to work with a CMO or CDMO on a drug API manufacturing project, the depth of the onboarding process dictates the success of the project. Onboarding is more than just signing a proposal and being introduced to the team. It’s a multi-faceted process that ensures everyone has done their due diligence and considered all of the project’s various components.

How to Set Your Pharmaceutical Contract Manufacturing Project Up for Success.

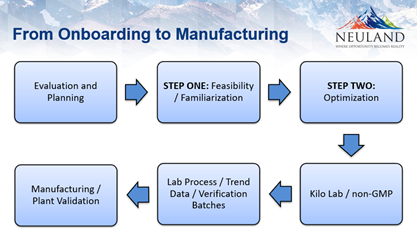

We are frequently asked what a pharma company working with a contract manufacturer should expect during onboarding. In this initial engagement, your CMO should be focusing on building a strong foundation for systems and processes. At Neuland, we call this the Evaluation and Planning phase. The goal here is to understand the marketing and product requirements. From there, a scientifically sound plan – a project roadmap – is created for project development and delivery.

The entire project initiation/onboarding process should involve representatives from every team involved in the project. You want to make sure all stakeholders are taking ownership and understand their roles.

A Focus on the Science.

A Focus on the Science.

The focus of any onboarding process should be on the science. The team will review information from literature or technical packages – including reaction conditions, isolation, characterization, quality and yields. As a part of this, they will also need to evaluate the safety requirements and understand the material balance and reaction mechanism for every step of the project. The more the contract manufacturing team can learn early in the process, the more successful the project will be later.

Concurrent with building this process understanding, the team will be identifying the costs of raw materials, relevant vendors, target timelines, licensing information and other logistics pertinent to the project’s successful execution. For example, at Neuland we’re vigilant about mapping out the manufacturing facility and equipment to ensure we’ve planned accordingly.

Address Potential Obstacles.

It’s no secret that no matter how much planning is involved, a project can still get off-track. A critical part of a solid onboarding process is anticipating and addressing obstacles. A proactive approach that identifies potential chemistry, analytical and practical challenges gives the team an opportunity to develop possible resolutions.

We find that this detailed preparation allows us to develop a systematic work plan which provides our customers with a smooth experience – regardless of what happens. This work plan must be approved by all the internal and external stakeholders involved in the process to ensure they understand the scope of the work and are prepared for execution.

In our experience, a collaborative approach is ideal as it leverages each person’s unique expertise. One way to ensure accountability is to use a responsibility assignment matrix. This is particularly helpful when projects include team members from numerous departments – such as Tech Transfer, Development QA, and Analytical.

A Robust CMO Onboarding Process Leads to Delivering Projects On-Time.

A finalized work plan marks the end of the onboarding process and provides a roadmap for the next steps – the first of which we call Feasibility/Familiarization.

This is where the science begins. Experiments are developed & launched in order to start learning about the process and develop recommendations. If adequate planning has been completed during onboarding, the team can quickly move through this phase and onto Step Two, Optimization.

Optimization.

Step Two is the part of the project where we prepare for – and launch – manufacturing. First, we ensure the process is robust and that we are consistently achieving maximum yield at the appropriate quality levels. We then make any final adjustments to processes and align all stakeholders in preparation for the final phase–manufacturing. With a robust onboarding process, manufacturing should be just as efficient and expeditious as in all the previous steps.

We know our onboarding procedures are rigorous, but we’ve designed them to ensure project success and customer satisfaction throughout the process. We have found that when a comprehensive onboarding process is implemented, the following steps go smoothly and are completed on time.

If your company is considering engaging a contract manufacturing partner, pay close attention to how robust their onboarding process is since it will have a lasting impact during your project.