Neuland has recently welcomed the addition of a new, dedicated Process Engineering Lab to its R&D Center. The lab opened in March, and supports operations and safety studies via a Quality by Design (QbD) approach.

Three Keys to QbD Success

The success of a QbD approach hinges on three fundamental elements. First, the target product profile must be clearly understood. This involves the second key element, determining the critical quality attributes (CQAs) that must be within a certain range limit or distribution according to the ICH guideline governing the product.

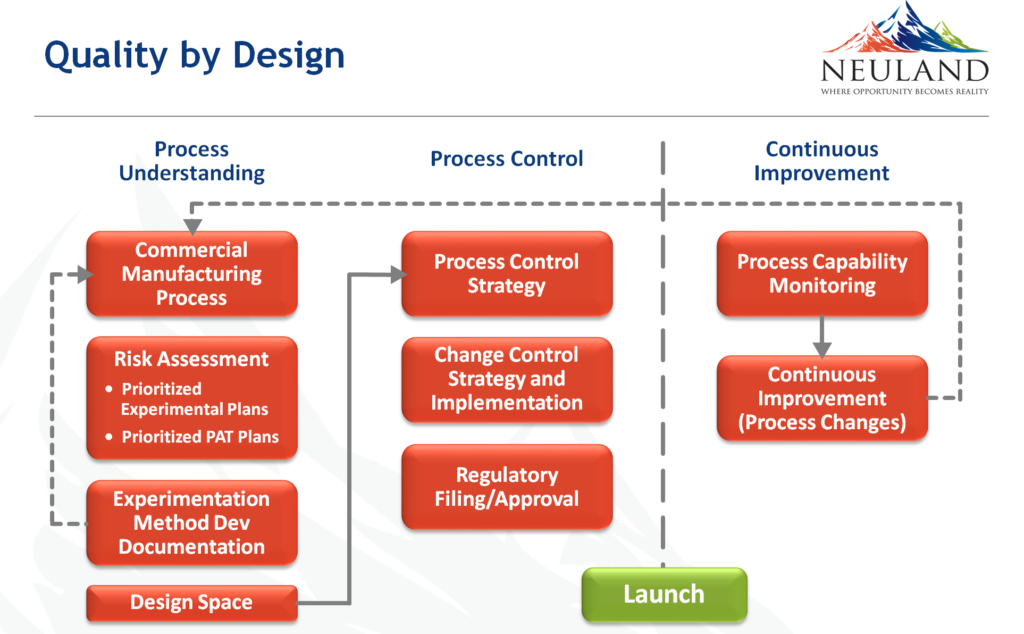

The third and final phase of QbD centers on the process needed to deliver the product. In this phase, risk assessments are used to gauge the impact of the raw material attributes and process parameters on the CQAs. Based on this, a design space is developed, and a control strategy is conceived and implemented.

The product lifecycle is then actively managed, with continual improvements made along the way, as shown in the flow chart below:

Taking Advantage of the Latest Equipment

In addition to a full range of state-of-the-art instrumentation and systems, the Process Engineering Lab features several innovative devices essential to the work it performs. An HEL reaction calorimeter and TSu (thermal screening unit) increases safety while enabling risk analysis and evaluation.

The reaction calorimeter is a stirred and controlled reactor that measures the rate of heat release as the reaction is conducted under controlled conditions. The TSu uses only approximately 0.5 to 5g of a sample, and provides clear data concerning hazards, including pressure. Specifically, the TSu indicates the thermal stability of chemicals, the safe process/handling temperature, and any potential temperature/pressure rise following exotherm.

The reaction calorimeter is a stirred and controlled reactor that measures the rate of heat release as the reaction is conducted under controlled conditions. The TSu uses only approximately 0.5 to 5g of a sample, and provides clear data concerning hazards, including pressure. Specifically, the TSu indicates the thermal stability of chemicals, the safe process/handling temperature, and any potential temperature/pressure rise following exotherm.

The HEL automated parallel reactors in the lab allow one chemist to perform multiple experiments, in parallel. Benefiting from precise stirring and temperature control, each experiment can be conducted at a separate temperature from -60 to 225C, and stirred separately, with different sized containers and different applications.

In addition, Design of Experiments software and Design Space methodology are used to create an optimal design.

The Process Engineering Lab will enable Neuland to continue meeting regulatory requirements, and providing quality products using cost-effective procedures. Through a scientific, risk-based approach, the work achieved in the Process Engineering Lab yields greater insight into active drug substance manufacturing process. The result includes improved scale-up efficiency and speed, and faster time to market.